Lab Experiments

LUNAR has proposed that the lunar farside radio telescope array be constructed by imprinting metallic dipoles on a thin, flexible substrate material and running transmission lines from the dipoles back to a center electronics package. We have chosen Kapton, a polyimide film that has been widely used in many space applications, as the framework material. It is light weight for transport and maintains its physical properties over large temperature ranges.

The objective of the following tests, conducted in the Lunar Simulation Laboratory (LSL) at the University of Colorado Boulder, is to determine if Kapton will be durable enough to last for at least one year on the lunar surface. The LSL consists of two thermal-vacuum chambers capable of reproducing the damaging conditions that can be found on the Moon. One chamber is larger and used for equipment components requiring an extremely clean environment. The second, newly built vacuum chamber contains JSC-1 lunar simulant regolith to more accurately model the lunar surface. The Kapton is thermally cycled from -150°C (simulating lunar night) and 100°C (simulating lunar day). During the day cycle, a deuterium Ultraviolet lamp is shined on the Kapton to mimic the solar flux near Lyman-alpha (121.6 nm).

The Facility

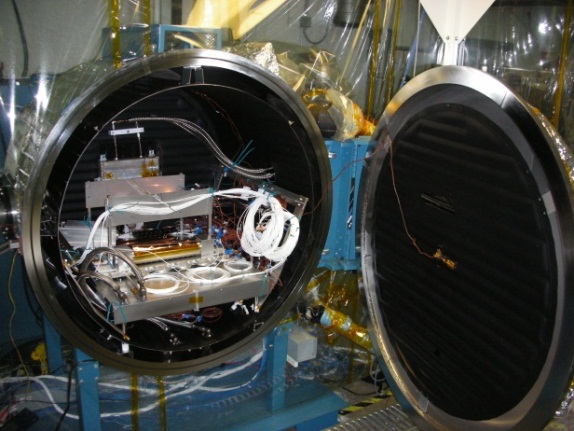

Above: This is LUNAR's clean vacuum chamber housed in a class 10,000 clean tent.

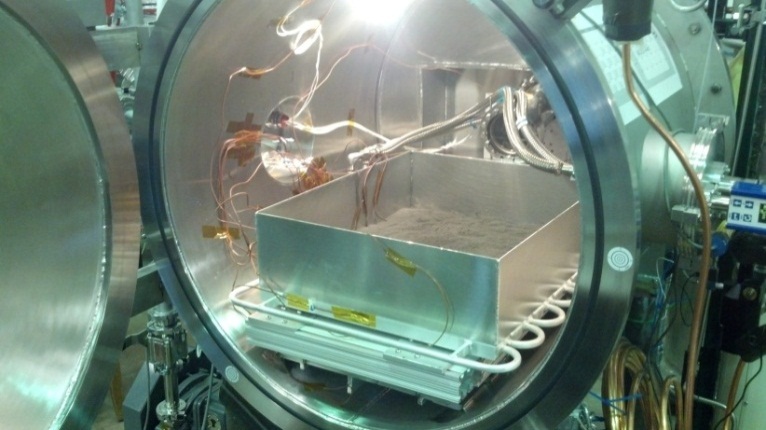

Below: The newly constructed Lunar Simulant Chamber houses a bed of JSC-1a regolith simulant.

The Team

Our team currently consists of six team members with backgrounds in astrophysics, aerospace engineering, and mechanical engineering.

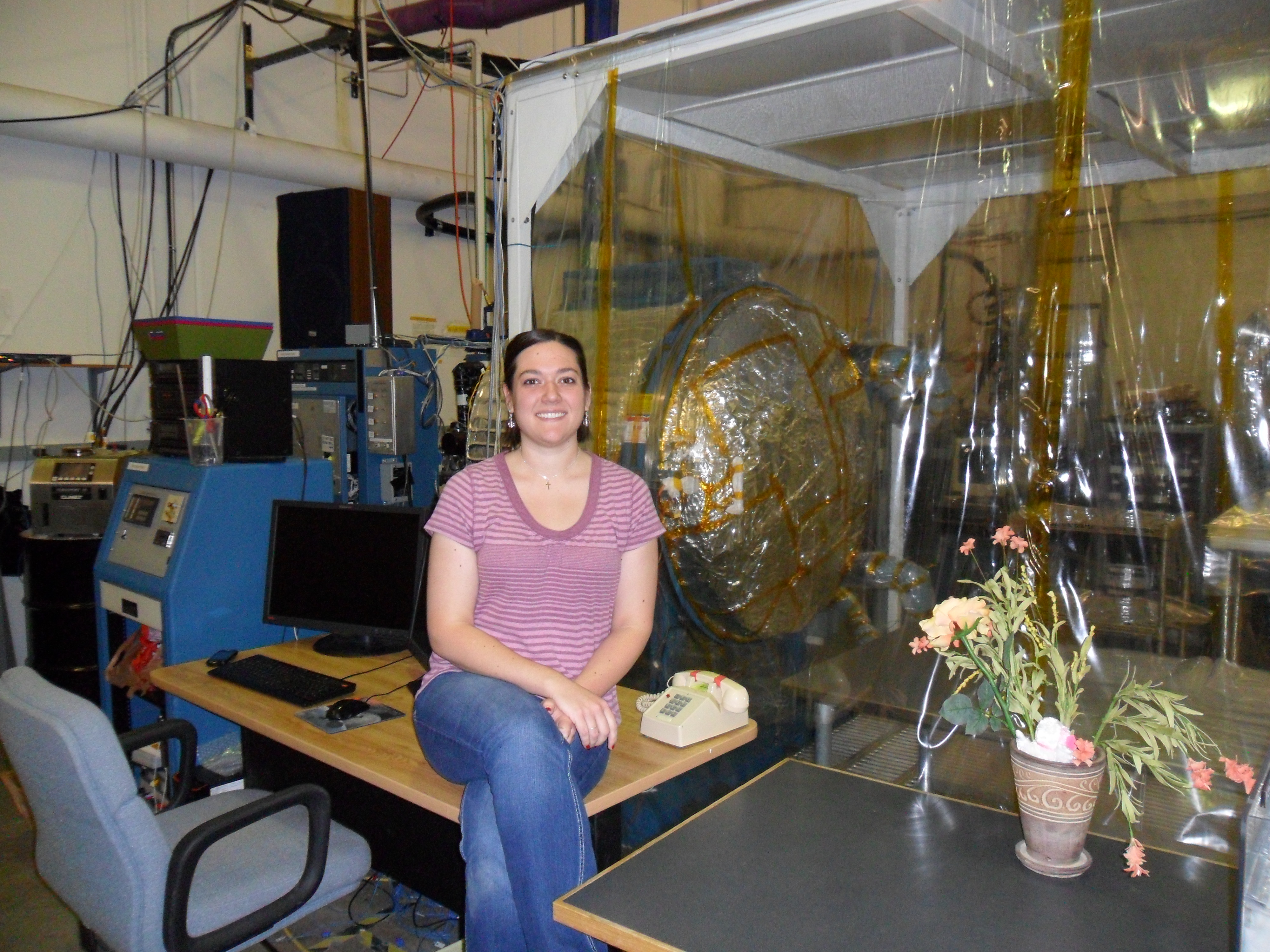

Above: Laboratory manager Laura Kruger

Above (Left to Right): Miles Crist (senior mechanical engineering undergraduate), Karynna Tuan (junior aerospace engineering undergraduate), Laura Kruger (Laboratory Manager), Kelsey Degeorge (junior mechanical engineering undergraduate), Chris Womack (sophomore mechanical engineering undergraduate).